CHALLENGE: Glacial Clays

To stabilize 5-ft diameter drilled shafts to a depth of 85-ft and to seal the sidewalls prohibiting the sandy soil from absorbing the slurry after competitor product failed.

SOLUTION

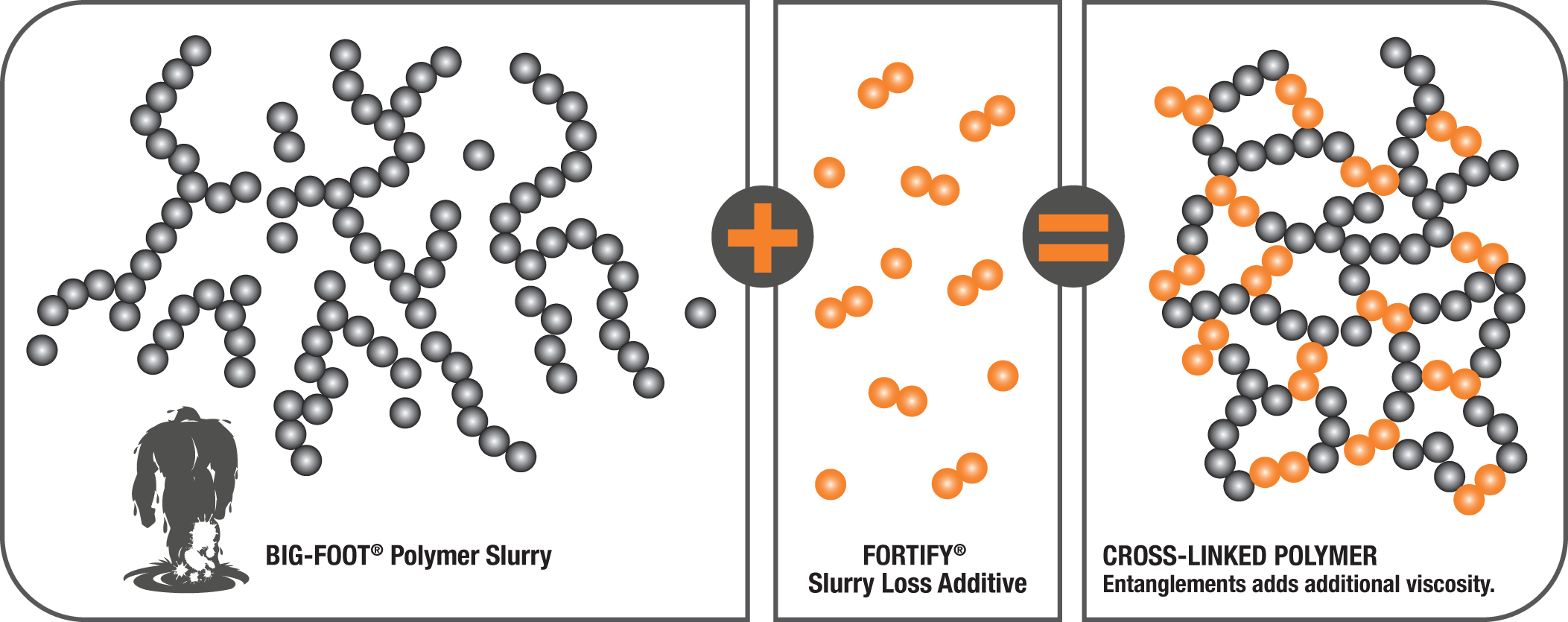

MATRIX studied the geology and developed a recipe for the slurry mix of BIG-FOOT® Polymer Slurry and FORTIFY® Slurry Loss Additive.

The project is a 210,000-sf expansion and 15,000-sf renovation of the existing medical center at grade. With a full basement and a parking garage below the basement level. Case Foundation from Phoenix, AZ drilled the 5-ft diameter piers that will support the structural columns that support this structure. Case Foundation is one of the most highly respected full service deep foundation specialist in North America.

The difficulty in installing the drilled shafts at this site was due to the geology. The soil consisted of brown dry medium dense poorly graded sand. The sand had only a 2-3% moisture content, and the water table was 115-ft below land surface. This resulted in the very dry sand absorbing the drilling slurry and causing extreme loss into the sidewalls of the drilled excavation.

The challenge was to stabilize the 5-ft diameter drilled shafts to a depth of 85-ft while sealing the sidewalls to prohibit the sandy soil from absorbing the slurry.

The competitor polymer slurry originally selected for use on this project had trouble stopping the slurry loss into the dry sand. MATRIX Construction Products was contacted by Paul Leclerc General Superintendent with Case Foundation to demonstrate our slurry productsat the site after the other slurry provider failed to solve the slurry loss problem.

MATRIX studied the geology and developed a recipe for the slurry mix. MATRIX mobilized to the site in 4-days and delivered the products. We also added GEO-NET® Slurry Loss Circulation Material directly at the drilled excavation into the slurry. MESH-SET® Granular Sealing Material was also added at the drilled hole into the slurry to aide in sealing the sidewalls and prohibiting the slurry from soaking into the sand.

We recommended a dosage of BIG-FOOT® Polymer Slurry and FORTIFY® Slurry Loss Additive to apply the required positive differential pressure against the sidewalls of the excavation. The concentration of BIG-FOOT, used for optimal concentration was 10.0 pounds per 1,000 gallons or 1.2 kilograms per meters cubed of water. At these concentrations, the Marsh funnel viscosity per quart of BIG-FOOT Polymer Slurry was 95 seconds per quart.

This slurry recipe stabilized the sandy soil with the dry polymer (BIG-FOOT®) as the primary building block combined with the second stabilizing polymer (FORTIFY®). A cross-linking effect was created within the slurry that sealed the drilled shaft excavation.

The result was that the client was able to complete the drilling of the foundation piers on the Yuma Medical center without any defects. The loss of slurry into the sand was interrupted and controlled by the recipe MATRIX recommended. This helped stabilize the soil and saved time and money.